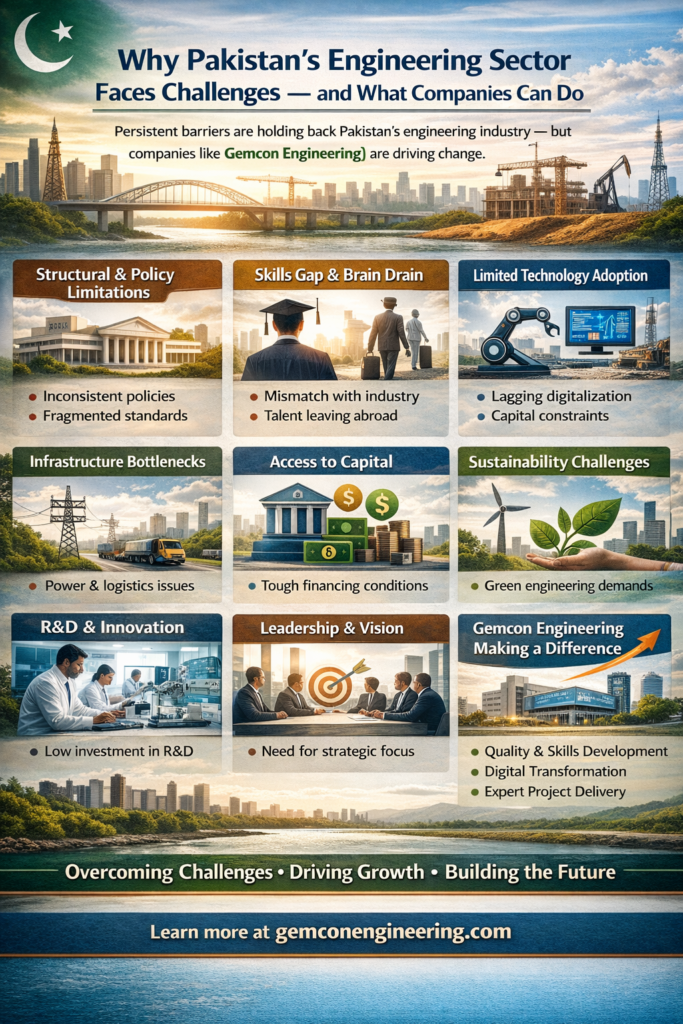

The engineering sector is vital to Pakistan’s economic development, underpinning infrastructure, manufacturing, energy, and industrial growth. Yet despite its potential, the sector continues to face persistent challenges that undermine productivity, competitiveness, and capacity to meet domestic and global demand. Addressing these challenges is essential not only for economic growth but also for meeting the needs of a rapidly growing population.

In this article, we explore the key barriers facing Pakistan’s engineering sector and practical strategies that companies — including industry leaders like Gemcon Engineering — can adopt to overcome these obstacles and foster a more resilient and innovative industry.

1. Structural and Policy Limitations

Inconsistent Industrial Policies

A major challenge for Pakistan’s engineering sector is the lack of stable and forward‑looking industrial policies. Frequent changes in regulation, tariffs, and import/export restrictions make it difficult for companies to plan long‑term investments. This uncertainty also discourages foreign direct investment (FDI) in technology and infrastructure.

Fragmented Industry Standards

Pakistan lacks unified national standards across many engineering disciplines. Without clear benchmarks for quality, safety, and performance, companies struggle to compete internationally. This fragmentation can also erode confidence among investors and clients.

What Companies Can Do

- Advocate for coherent, long‑term industrial policies through industry associations.

- Collaborate with regulatory bodies to help shape standards that are internationally competitive.

- Adopt internal quality benchmarks aligned with global best practices to bridge the gap where national standards are weak.

2. Skills Gap and Human Capital Challenges

Mismatch Between Academia and Industry

One of the most pressing issues is the persistent gap between what universities and technical institutes teach and the skills required by modern engineering firms. Graduates often lack practical experience, exposure to cutting‑edge tools, and an understanding of global engineering standards.

Brain Drain

Talented engineers frequently seek opportunities abroad due to limited career growth, inadequate compensation, and better working conditions in developed economies. This migration deprives Pakistan’s engineering ecosystem of vital expertise.

What Companies Can Do

- Establish partnerships with universities to jointly design curricula tailored to industry needs.

- Offer internships, apprenticeships, and on‑the‑job training programs that build real‑world skills.

- Implement retention strategies such as competitive compensation, leadership pathways, and continuous professional development.

3. Limited Technological Adoption

Lagging Behind in Digital Transformation

While global engineering industries embrace digital tools like automation, AI, BIM (Building Information Modeling), and IoT (Internet of Things), many Pakistani firms still rely on traditional processes. This slows productivity, reduces project accuracy, and increases costs.

Capital Constraints

Investing in state‑of‑the‑art technology requires substantial capital — something many local engineering firms lack, especially small and medium enterprises (SMEs). Limited access to financing further compounds this challenge.

What Companies Can Do

- Prioritize incremental technology adoption — starting with affordable digital solutions that offer clear returns.

- Partner with technology providers and tech incubators to pilot innovation initiatives.

- Seek financing through development funds, industry consortiums, or public‑private partnerships to invest in digital tools.

4. Infrastructure Bottlenecks

Power and Logistics Challenges

Unreliable power supply, outdated logistics networks, and high transportation costs have a direct impact on engineering project execution. Delays and cost overruns become a norm rather than an exception.

Regulatory Delays

Approvals for construction, environmental compliance, and land use often take months or years to secure. These delays erode profit margins and discourage investment in large projects.

What Companies Can Do

- Invest in backup power solutions and explore renewable energy to reduce operational disruptions.

- Leverage technology to optimize supply chain and logistics planning.

- Engage proactively with government agencies to streamline approval processes and highlight bottlenecks affecting the sector.

5. Access to Capital and Financing

Underdeveloped Financial Ecosystem

Banks and financial institutions in Pakistan have often been reluctant to finance engineering and infrastructure projects due to perceived risk. High interest rates and stringent collateral requirements make borrowing costly and inaccessible for many firms.

What Companies Can Do

- Explore alternative financing options, such as venture capital, impact investors, and infrastructure bonds.

- Build strong financial models that clearly demonstrate ROI to attract investment.

- Join industry associations that can collectively lobby financial institutions for more favorable lending terms to engineering firms.

6. Sustainability and Environmental Considerations

Growing Global Focus on Green Engineering

International clients increasingly require compliance with environmental and sustainability standards. However, local firms may lack the expertise or resources to deliver eco‑friendly engineering solutions at scale.

What Companies Can Do

- Develop sustainability roadmaps that align with global engineering and construction practices.

- Invest in training staff on green engineering principles and certifications.

- Lead by example by adopting energy‑efficient processes and sustainable materials in projects.

7. Innovation and Research & Development (R&D)

Underinvestment in R&D

Engineering innovation thrives where companies invest in research. In Pakistan, R&D expenditure as a percentage of GDP remains low compared to global peers, limiting breakthroughs in materials, technologies, and processes.

What Companies Can Do

- Allocate dedicated R&D budgets focused on solving local engineering challenges.

- Collaborate with academic institutions and tech startups to co‑develop innovative solutions.

- Participate in international research networks to stay ahead of technological trends.

8. Role of Leadership and Strategic Vision

Successful transformation requires visionary leadership willing to take calculated risks, invest in talent, and embrace change. Firms that remain static risk falling further behind global competitors.

Leadership Priorities

- Embed a culture of innovation and continuous improvement.

- Foster cross‑disciplinary collaboration within organizations.

- Develop long‑term strategic plans that are adaptable to market shifts.

How Companies Like Gemcon Engineering Are Making a Difference

Leading firms — such as Gemcon Engineering — are demonstrating how proactive strategies can help overcome these systemic challenges. By marrying technical expertise with strategic investments in skills, technology, and partnerships, such companies act as catalysts for sector‑wide improvement.

For example:

- Gemcon Engineering’s focus on quality assurance, project management excellence, and client‑centric solutions sets benchmarks for competitors.

- Their commitment to training and development programs strengthens the engineering talent pool within Pakistan.

- Strategic adoption of digital tools enhances productivity and precision in project execution.

By modeling best practices and engaging with stakeholders across academia, government, and industry, pioneering firms create momentum for broader transformation.

Conclusion

Pakistan’s engineering sector stands at a critical juncture. While the challenges are significant — from policy inconsistencies and skills gaps to limited access to capital and technological lag — they are not insurmountable. With strategic leadership, collaborative policy advocacy, investment in human capital, and a willingness to embrace innovation, engineering firms can unlock growth and competitiveness.

For companies like Gemcon Engineering and others willing to lead by example, the path forward lies in aligning technical excellence with strategic vision. Through sustained effort and forward‑thinking initiatives, Pakistan’s engineering sector can not only rise to meet domestic needs but also compete on the global stage.