The construction industry in Pakistan has entered a period of strategic recalibration. With inflation, global supply chain disruptions, and shifting economic policy, builders and developers are confronting a new reality: material costs are more volatile and unpredictable than ever before. To navigate this uncertainty, it’s essential to understand material cost forecasts and plan budgets accordingly — not just to protect profit margins, but to ensure projects remain viable and competitive.

At Gemcon Engineering, we’ve compiled a detailed look at what builders should expect in the coming year and how to strategically budget for key construction materials.

Why Material Cost Forecasting Matters More Than Ever

Material cost forecasting isn’t just about estimating prices — it’s about managing risk and protecting project profitability. A miscalculation on material costs can:

- Blow out project budgets

- Delay completion timelines

- Reduce profit margins

- Increase disputes between contractors and clients

In the current Pakistani context, factors like inflation, government policies, currency fluctuation, and global commodity trends all influence the prices of essential building materials.

Forecasting helps builders make informed decisions, lock in prices where possible, and manage client expectations with transparency.

Key Construction Materials: What to Budget For

Let’s break down the major materials used in construction, current price pressures, and projected trends for the next year.

1. Cement

Overview: Cement is the backbone of modern construction. Its price significantly impacts overall project costs.

Recent Trends: Cement prices in Pakistan have seen intermittent increases due to higher energy costs, logistical issues, and production capacity constraints in parts of the country.

Forecast for Next Year:

- Expect modest price increases tied to energy cost fluctuations.

- Export demand from neighboring markets could influence domestic supply.

- Government policies affecting duty on imported clinker may also impact pricing.

Budgeting Tip: Consider securing long-term supply agreements with manufacturers at fixed rates to hedge against inflationary spikes.

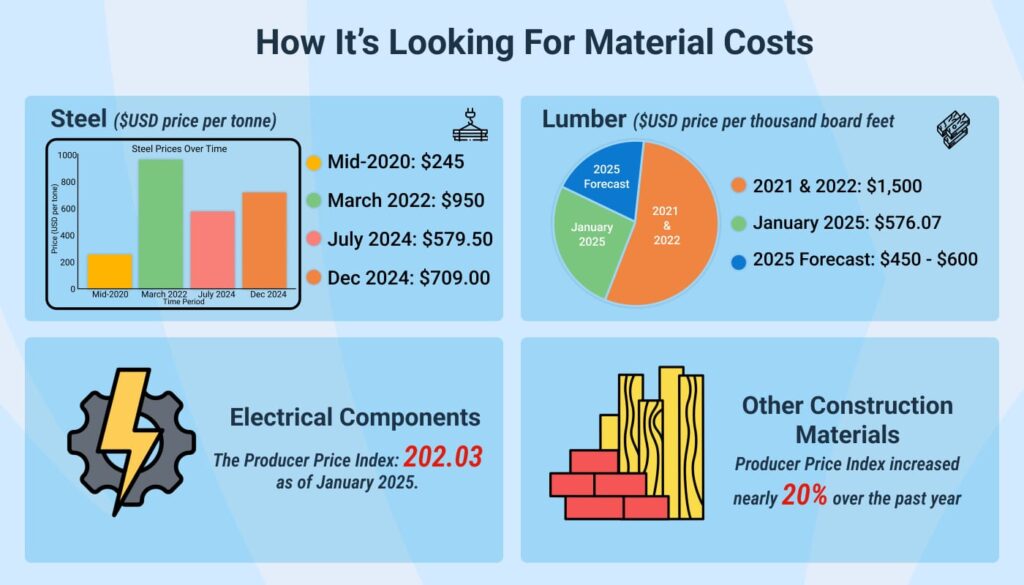

2. Steel (Rebar & Structural Steel)

Overview: Steel reinforces concrete and is essential for frames, beams, and columns.

Recent Trends: Global steel demand and supply chain challenges have caused significant price volatility over the past few years.

Forecast for Next Year:

- Prices are expected to remain sensitive to global commodity markets.

- Transportation costs and currency value can further impact imported steel pricing.

- Local production capacity improvements may help stabilize costs.

Budgeting Tip: Lock in steel prices early in the project cycle. If possible, negotiate volume discounts with suppliers or consider phased procurement aligned with project milestones.

3. Bricks & Blocks

Overview: Bricks remain a primary building material across Pakistan, especially for walls and partitions.

Recent Trends: Traditional brick kilns are adjusting to environmental regulations, which can affect production costs.

Forecast for Next Year:

- Bricks may see moderate cost increases depending on fuel pricing and regulatory shifts.

- Hollow concrete blocks may become more competitive as builders shift toward more efficient alternatives.

Budgeting Tip: Evaluate the mix of materials — in some cases, concrete block solutions can be more cost-effective without sacrificing structural performance.

4. Sand & Aggregates

Overview: Sand, gravel, and crushed stone are required in large quantities for concrete and mortar mixes.

Recent Trends: Regulatory crackdowns on illegal mining have occasionally restricted supply, pushing prices upward.

Forecast for Next Year:

- Prices are likely to fluctuate based on availability and enforcement of mining regulations.

- Urban projects may incur higher transportation costs due to distance from natural deposits.

Budgeting Tip: Plan early logistics and negotiate supply contracts that include transportation to prevent last-minute cost escalations.

5. Paints & Finishes

Overview: While not as heavy a cost factor as structural materials, paints, tiles, and finishes significantly influence final budget allocations.

Recent Trends: Imported paint components and chemicals have seen varied cost pressures due to currency changes.

Forecast for Next Year:

- Expect moderate price increases tied to global chemical markets.

- Local manufacturing expansion may help balance costs.

Budgeting Tip: Select suppliers who offer price protection packages or bulk-purchase discounts for recurring finish materials.

6. Electrical & Plumbing Supplies

Overview: These are critical for functional infrastructure within buildings.

Recent Trends: Rapid urbanization and growing demand for quality fittings have driven up demand.

Forecast for Next Year:

- Prices will be influenced by international hardware markets and domestic production capacities.

- Electrical conduit, wiring, and pipes may see moderate increases tied to raw material costs.

Budgeting Tip: Include allowances for hardware price variation — especially for imported fixtures, which are more sensitive to exchange rate changes.

External Factors Influencing Material Costs

Next year’s material cost forecast can’t be discussed without understanding the major forces driving price changes:

1. Inflation & Currency Fluctuations

The Pakistani rupee’s performance against major currencies directly affects the cost of imported materials and equipment. A weaker rupee can make imports significantly more expensive, directly increasing the cost base for builders.

Action: Maintain visibility over foreign exchange trends and consider importing materials early if financially viable.

2. Fuel & Transportation Costs

Fuel is a key driver of logistics expenses. Given the current global energy market dynamics, transportation costs for heavy materials like steel and cement can vary significantly.

Action: Negotiate arranged transport contracts early in the project lifecycle to avoid last-minute price surges

3. Global Supply Chain Dynamics

International production slowdowns, port congestions, or trade restrictions can all lead to shortages or price spikes.

Action: Diversify your supplier base where possible to reduce dependency on any single source.

4. Local Government Policies

Tax changes, import duties, or construction-related regulatory measures can indirectly affect material prices.

Action: Keep abreast of policy changes and budget conservatively to account for potential fiscal shifts.

How Builders Should Approach Budgeting

Here’s a practical framework for building a resilient material cost budget next year:

1. Use Tiered Forecasting

Rather than a single cost estimate, prepare tiered forecasts (e.g., conservative, moderate, and high-impact) to allow flexibility if market conditions change.

2. Plan for Phased Procurement

Secure materials in phases matching project milestones to minimize capital lock-in and adapt to price changes.

3. Build Contingency Buffers

Allocate a contingency budget (typically 10–15% of material costs) to accommodate unexpected price increases.

4. Negotiate with Suppliers

Establish long-term relationships with reliable suppliers. Contract clauses that lock in price ranges or offer rebates can protect builders from sharp fluctuations.

5. Monitor Market Signals Regularly

Regularly reviewing commodity indices, industry reports, and price trends enables proactive adjustments rather than reactive cost control.

The Strategic Advantage for Gemcon Engineering Clients

At Gemcon Engineering, we understand that material costs are one of the biggest uncertainties in construction budgeting. With years of project experience across residential, commercial, and institutional builds, we help our clients:

- Forecast realistic material budgets

- Secure reliable supply chains

- Leverage cost-efficient alternatives without compromising quality

- Structure contracts that balance risk and reward

Whether you’re planning a small renovation or a large-scale construction project, proactive budgeting — grounded in a solid understanding of material cost forecasts — is essential for success.

Final Thoughts

Budgeting for construction materials in Pakistan’s evolving economic environment requires research, strategy, and flexibility. By anticipating cost patterns, building contingency into budgets, and working with experienced partners like Gemcon Engineering, builders can protect profitability and ensure smooth project delivery.

If you’d like personalized support in building your next project’s material budget or want a custom cost forecast, don’t hesitate to reach out to Gemcon Engineering today!